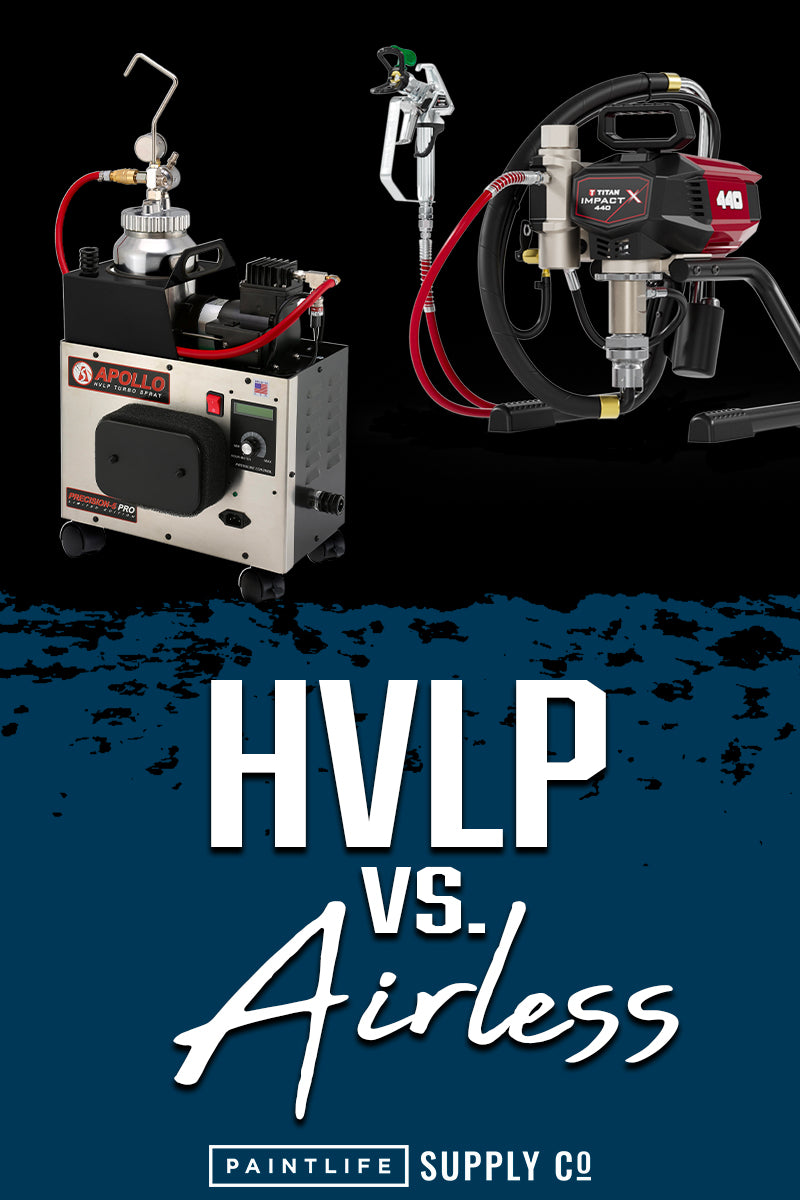

HVLP vs Airless Sprayers

Paint sprayers make it simple to complete any painting project in a fraction of the time without dealing with sticky rollers, brush lines, dropping paint, or the trouble of trying to coat varied surfaces equally.

HVLP (high volume, low pressure) and airless paint sprayers are popular tools for painting large surfaces, but they work differently. HVLP sprayers use a fan to atomize paint into a fine mist, while airless sprayers use high pressure to force paint through a nozzle.

Before jumping to the differences, let’s understand the basics -

What Exactly Are HVLP Paint Sprayers?

HVLP sprayers, or turbo-sprayers, are professional spraying machines used for trim, staining, finish work, cabinet painting, and other precise applications that require great accuracy, higher speed, and a smooth finish.

HVLP guns can control the equal distribution of paint with a larger volume of paint and lower air pressure, saving you money by reducing paint waste from overspray and splattering.

How Does the HVLP Spray Gun Function?

HVLP paint sprayers "atomize" the paint, which means that when it comes into contact with the spray gun's airflow, it splits into small particles as soon as the air passes outside the nozzle. HVLP sprayers provide you with complete control over fan size & spray density.

These sprayers contain airflow and volume controls, a paint store, an air intake, and a nozzle to manage the pressure and distribution of the sprayed paint. When the release button on the spray cannon is pressed, the inside paint is atomized, shot at the proper pressure, and dispersed via the nozzle.

What Exactly Are Airless Sprayers?

Airless Paint Sprayers don’t use air mechanisms like a turbine or an air compressor. Instead, they use an internal piston pump to immediately pressurize the substance before transferring it through a pipe to the spray gun. When the pressurized liquid splatters on the spray tip as it exits the nozzle, it is pushed too atomize.

The high pressure applied to the spray tip breaks the paint into the atomized particles needed for painting. As a result, they are designed to spray vast areas at maximum strength at all times.

How Does Airless Spraying Work?

Airless sprayers are used when covering huge surface areas at high volumes and fine details. They apply thick, heavy coats quickly; however, this comes at the expense of higher overspray and bigger droplets. Because these guns run at significantly greater pressures, they can frequently use thicker paint straight from the can without first filtering or decreasing it.

HVLP vs Airless Sprayers

| Features | HVLP Sprayers | Airless Sprayers |

| Pressure |

HVLP sprayers operate at a much lower pressure than airless sprayers. 4.5 PSI vs. 2200 PSI. They have high volume, low pressure & minimal overspray. |

While airless sprayers have high volume and high pressure but more overspray, there is a serious health risk of getting injected with paint from an airless paint sprayer. |

| Quality Finish | HVLP sprayers produce a finer finish than airless sprayers. This is because the paint is atomized into a finer mist, which results in a more even coat. | They are less refined compared to HVLP sprayers but help in quicker coatings. |

| Waste | HVLP sprayers produce less overspray. Due to the lower pressures of an HVLP, you have a much greater transfer rate of your coating to the surface. | The wastage is a bit high in airless sprayers as they have more overspray. |

| Speed | In terms of speed, HVLP has less speed. If you want a fine finish, HVLP sprayers are a good option. But if you are looking for a fast way to paint large surfaces, airless sprayers are a good option. | Airless sprayers are faster than HVLP sprayers. This is because they use high pressure to force paint through a nozzle to cover more ground in less time. Airless sprayers are better for higher volume projects like the trim and doors in an entire house. |

| Atomization | Air and paint collide outside the tip. | Airless sprayers are atomized at the spray tip and can handle thicker material. |

| Delivery | A turbine or air compressor and a hose are used. | No air compressor or turbine is used to pressurize the material. |

| Paint Holding Capacity | HVLP has a good capacity for storing paint in a separate, sealable, interchangeable container. | They cannot hold paint, and you must wash out the hose, pump, and lines after using the sprayer. |

| Application | The paint is applied slowly, but it has precise application. | The paint is applied faster, with extensive coverage, but cannot be used for detailed work. |

| Coatings |

While HVLP sprayers are versatile, they perform best with thinner coatings. Their low-pressure delivery mechanism produces a fine mist, ideal for attaining a faultless finish with enamels, stains, and varnishes. |

Airless sprayers excel at handling thick coatings, making them the tool of choice for tough jobs. When working with latex paint or other heavy materials, the high pressure of an airless sprayer ensures a flawless application. |

| Suitability | Best suited for intricate projects and detail work. | They are more suitable for covering large areas and broader surfaces. |

Here are some factors to consider when choosing a paint sprayer:

- The type of paint you are using

Some types of paint are better suited for HVLP sprayers. Other types of paint are better suited for airless sprayers. While considering the viscosity and composition of your paint, you can choose which is most suitable.

- The size of the surface you are painting

An airless sprayer may be a better option if you paint a large surface. HVLP sprayers are not as efficient for large surfaces.

- Your budget

HVLP sprayers are generally less expensive than airless sprayers. Making them ideal for DIY enthusiasts.

- Your experience level

HVLP sprayers can be more difficult to use than airless sprayers. If you are still unsure which type of paint sprayer is right for you, it is always best to consult with a professional. The Apollo Precision 5 Pro LE with remote pot is the Lamborghini of HVLP sprayers. While supplies last, you get a second Atomizer gun and quart pot. The TriTech T4 airless starter kit is a quick and easy way to get everything you need to spray with an airless sprayer.

What Materials Work Well With HVLP Sprayers?

Oil-based paint is suitable for using HVLP paint sprayers. Paints with a higher viscosity, such as water-based latex, can clog the sprayer. Before using latex paint in an HVLP gun, combine a half cup of water for every gallon of latex paint in a bucket and thoroughly stir to dilute its consistency.

- Wall paints for interior use

- Chalk paint

- Paint

- Varnishes

- Oil paint

- Primers

- Wood preservative

What Applications Are HVLP Sprayers Appropriate For?

The HVLP paint sprayers can be utilized for a variety of applications. There is always a sprayer to meet your needs, whether for interiors or exteriors. Here are a couple of such examples:

- 2/ 2 ceilings

- Doors and Windows

- Garage doors

- Summer residences

- Garden Furniture and Objects

- Fences and railings

- Furnishings

- Decorative items

What Materials Work Well With Airless Paint Sprayers?

Airless paint sprayers can be used to spray a variety of materials. We have compiled a list of them here:

- Paints, varnishes, lacquers, oils, and separating agents based on water or solvents

- Paints based on synthetic resins, PVC paints, and 2-K lacquers

- Fillers and primers

- Paints for fireproofing and corrosion protection

- Latex paints, emulsions, adhesives, and sealants

- Paint for masonry, roof linings, floor coatings, and silicon resin paint

- Fillers and other compounds with a high viscosity

What Are the Airless Paint Sprayer Applications?

Airless paint sprayers are useful for a wide range of applications. Paint and materials can be applied on the following things, whether inside or outside, for example:

- Radiators

- Windows and doors

- Ceilings and walls

- Constructions made of wood and steel

- Exteriors

- Brickwork

- Roofing materials

Note: Always refer to the manufacturer’s instructions for specific details on selecting paint for your painting projects.

Check Out Our Professional Sprayers

The best HVLP paint sprayer: Apollo Pro Pro LE & Remote pot is a sign of perfection for HVLP fans. This tool provides unrivaled performance and finesse.

The TriTech T4 Airless Starter Kit is your ticket to efficient painting in the airless category. This package includes everything you need to start airless spraying quickly and easily.

Final Verdict

Airless sprayers hold the upper hand when it comes to speed. Their high-pressure system allows for rapid paint application, making them ideal for large-scale projects.

The choice between HVLP and airless sprayers ultimately boils down to the nature of your project. If you tackle large surfaces and aim for fast coverage, an airless sprayer is your best bet. On the other hand, if precision, control, and a professional finish are your priorities, an HVLP sprayer is the way to go.

Before investing in airless systems, consider the size of your project, the type of surface you're working with, and the level of finish you desire. Armed with this knowledge, you'll be better equipped to choose between airless sprayers' power and HVLP tools' finesse. Whichever path you choose, remember that quality tools will always lead to professional results.

1 comment

Fantastic information. Thank you so much for sharing