The Perfect Stain

If you’ve seen some of my recent projects or videos across social media, then you’ll know that in the last six months, I’ve started using Stain & Seal Expert’s products and I absolutely love them! Caleb & Ashley Roth founded Stain & Seal Experts in 2012 as a small family-owned and operated Nashville based fence and deck staining company. Today, they not only run Nashville’s oldest, most trusted staining and sealing company, but they manufacture and distribute oil-based stains, sealers, and wood-restoration chemicals. They have become a nationwide brand that is making a positive impact on the industry. Stain & Seal are true experts in the fence, deck and house staining, wood restoration, and log home restoration trades. You can trust them with any project from pre-staining wood to cleaning and restoring your aged structure.

The Product

Expert Stain & Seal’s stains are top-of-the-line and unlike any oil-based stain I’ve ever used. They feature several key features that set them apart, on top of having sealing properties that protects your wood from warpage, cracking, chipping, and twisting. On top of this, they maintain ultra low VOC (volatile organic compounds) levels, which makes it healthier for the environment. These stains pass regulations in all fifty states and the UK. Backed by a two year manufacturers warranty, you’ll find these stains easy to apply and you can find comfort knowing that they are trusted by thousands of homeowners and contractors alike.

Non-drying: One of my favorite features of these stains is the fact that they are non-drying oils. When staining a deck or fence, there’s no need to mask off metal hardware - you can simply wipe it off at the end of the job. The product will never dry on the surface! This leaves for easy cleanup - water with Dawn dish soap will be your best friend. Make sure you wipe off excess on flat surfaces, as if the board is fully saturated, the excess will become tacky as it will never dry. If you have a large stack of freshly stained wood that you’re downstacking, they won’t stick together and need to be peeled apart - benefits of being a non-drying oil. Avoid using non-drying oils in an area where caulking and sealants might need to be used in the future, as they will likely not stick well to surfaces with a non-drying oil.

Self-leveling: When pre-staining individual boards and handling them, you might be worried about your fingerprints leaving marks in the wet wood. With these stains, there’s no need to worry! As the wood begins to penetrate and dry, it will self-level, creating a flat and even surface across the wood to fill every fiber. Kiss those fingerprints goodbye! When brushing or spraying vertical surfaces, because of the self-leveling feature, you won’t see any drips or runs - the grass below decks and fences will be safe!

Penetrating: These stains will keep on penetrating. If you’re staining a deck where you’ll only ever see one side of the wood, trust that if you flipped the boards over, it’ll look just as good! The self-leveling and penetrating aspects of these stains go hand in hand - this stain will penetrate every fiber to become fully saturated and generate an amazing look, enhancing the beauty of the wood. Because of this, your wood will last longer than when compared to using other products

Flash Point: While most other products might have a flash point of anywhere from 90-100°F, Expert Stain & Seal’s stains feature a flash point of up to 400°F for their products. This is a game changer, as in the past, I’ve had buckets of oil-soaked rags catch on fire on a hot summer day! Many contractors work all year-round, and especially in the heat, so ease your mind knowing that this product won’t spontaneously burst into flames.

These Expert Stain & Seal stains are available now for purchase on paintlifesupply.com

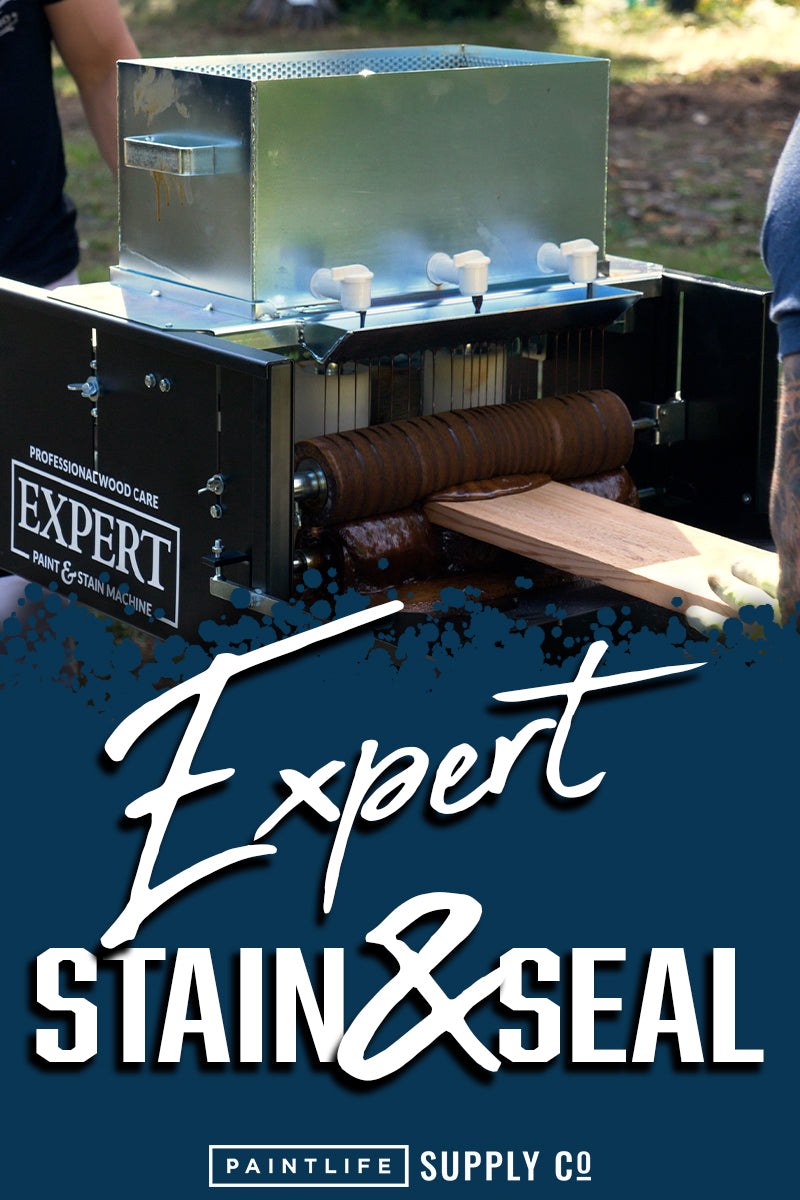

The Machine

On top of making stains, this company has also created the Expert Staining Machine which is a manually operated machine that pre-stains and pre-paints lumber, wood, and interior trim. Feed boards as large as 4x12” through it - it rolls and back brushes all in one go. Simply pour your stain into the top of the machine, and easily control the flow rate with a few valves. Collect the excess with a bucket and strainer underneath the machine to make the most of your stain. Nothing goes to waste. See it in action in this video!

This is a two person process - one person feeds the board through on one side, and the other person catches it on the other side. One pass through will be enough, but on the first board, you might need to let it go through a few times to fully saturate the brushes and rollers inside the machine. My process is to stack the boards vertically for the first hour, then downstack them somewhere safe to finish the drying process before installation.

Run stain or paint through this machine - you can even pre-paint trim before installation with this machine. If you were so inclined, you could even turn this machine into a side hustle - go ask some fence companies if they need someone to pre-stain some wood for them.

The stain machine is also easy to clean out - simple thumb screws allow you to remove the four foam rollers and twelve brushes. If paired with Expert Stain & Seal’s stains, you can simply throw the used brushes and rollers in a bucket if you’ll be using the same color next time. Then easily clean out the rest of the stain machine with some warm water and Dawn dish soap - even Crocodile Cloths will work. The process might take a little bit longer compared to cleaning an airless sprayer, but think of the time this machine will save you in the long run! Just remember not to clean this stain machine out on any driveways, walkways, or in grassy areas.

Tips for Decks

When using these stains, I’m most likely doing projects related to decks and fences, and I’ll walk you through some tips and tricks to completing those jobs with Expert Stain & Seal stains! The first thing you’re going to want to do is get right into sanding. If you’re using brand-new wood, there might be a mill-glaze on the surface; mill-glaze is the glossy-like film that develops on lumber during the production process. Sanding the wood with at least an eighty grit sandpaper will allow the wood to soak up more stain - I’m typically using a 5” sander for larger areas, and a 3x4” sander for smaller areas and edges.

When staining anything, you definitely should use a colored stain rather than a clear. A colored stain will contain properties that protect from UV rays and weather - prolong the life of your wood, even if the stain has a slight pigment to it, to let the natural color shine. Or just use the color “natural”! Additionally, water-based products also will not increase the life of your wood - penetrating oils will keep the wood fibers from drying out.

Before beginning the staining process, remember to stir your stain. Pigment can settle on the bottom, so give it a good mix to ensure proper color throughout. Depending on the size of the deck, I might just use a stain brush for ease, and to not worry about overspray. Otherwise, you’ll need to do some masking off of nearby surfaces - but remember, you can wipe off metal hardware easily with this non-drying oil! Apply a nice heavy coat, really saturate the wood, and it’ll start penetrating quickly. Wipe the excess pooling stain off, and then you can walk on it as soon as it’s soaked in!

Tips for Fences

If your next project is to stain an existing fence, then you’re most likely going to be using an airless sprayer to get the job done - a whole other game compared to using a brush! Some of the tools I’ll have with me include: cardboard shields, a hand masker with plastic on it, a respirator and Tyvek suit. Mask off any surfaces that you don’t want any overspray to get onto with the hand masker, and use the cardboard shields under the fence to protect the grass. The other two items are both essential PPE (personal protective equipment) to protect you and anyone else on the jobsite.

While this product doesn’t need to be back brushed, I am always a fan of using a 6” Goliath brush attached to an extension pole to promote adhesion and penetration even more so. It doesn’t hurt to be thorough. With the airless sprayer, my preference is to use a 515 tip to help control overspray, and to turn the PSI down to the 500-600 range. I would recommend not using a fine finish tip, as those will create more overspray.

Additionally, holding a cardboard shield while you spray is another method to control overspray. Hold it behind the top of the pickets when spraying the upper portion of them, to catch any overspray going over the fence. Additionally, you should be spraying at an angle to get the stain on the sides of the pickets, but not straight-on enough to send overspray through to the other side. When backbrushing, have your brush filaments facing up to avoid pooling of the product!